Cemented Tungsten Carbide Strip

Cemented Tungsten carbide is a sintered metallurgical product of powder form. It is manufactured in vacuum or Hydrogen reduction furnace with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni) or Molybdenum (Mo) as the binder.

Cemented Tungsten carbide has many excellent characteristics such as high hardness and strength, good wear and corrosion resistance and salient stability under high temperature (even at 500 ºC it is essentially unchanged and at 1000 ºC it is still of high hardness). It can be used to cut cast iron, nonferrous metals, plastics, chemical fiber, stainless steel and high Manganese steel, etc., and make drilling tools, mining tools, measuring gauges, wear parts, cylinder liners, precision bearings, nozzles and metal molds, etc..

Stanford Advanced Materials provides various machined cemented Tungsten carbide products of different forms such as rod, strip, mill and drill, cutter/tip, nozzle, dies and complex parts, etc..

We supply three types of cemented Tungsten carbide strips: strip with angle, round strip and cemented Tungsten carbide strip.

Specifications of cemented Tungsten carbide strip:

Size (T x W x L, mm) |

Thickness Tolerance (mm) |

Width Tolerance (mm) |

Length Tolerance (mm) |

|---|---|---|---|

1 x (2 ~ 5) x L |

Thickness = 7.0, Thickness > 7, |

Width = 30, Width> 30, |

Length<100, 100≤Length<200, Length = 200, |

1.5 x (2 ~ 10) x L |

|||

2.0 x (3.5 ~ 15) x L |

|||

2.5 x (2.5 ~ 20) x L |

|||

3.0 x (3.0 ~ 20) x L |

|||

3.5 x (3.5 ~ 25) x L |

|||

4.0 x (4.0 ~ 30) x L |

|||

5.0 x (4.0 ~ 40) x L |

|||

6.0 x (5.0 ~ 40) x L |

|||

(7 ~ 20) x (7 ~ 40) x L |

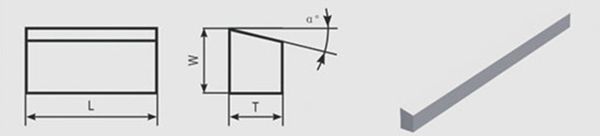

Specifications of Cemented Tungsten carbide strip with angle:

Size (T x W x L, mm~α,°) |

Thickness Tolerance (mm) |

Width Tolerance (mm) |

Length Tolerance (mm) |

Angle Tolerance (°) |

|---|---|---|---|---|

(1 ~ 2) x (2.5 ~ 6.0) x L ~ (0 ~ 35) |

0/+0.2, 0/+0.5 |

0/+0.2, 0/+0.6 |

L<100, Tolerance: 0/+1.0; L = 100, Tolerance: 0/+2.0; L = 300, Tolerance: +0.5 |

+/-1 |

(2 ~ 3) x (3.0 ~ 8.0) x L ~ (0 ~ 35) |

||||

(3 ~ 4) x (3.0 ~ 20) x L ~ (0 ~ 35) |

||||

(4 ~ 5) x (4.0 ~ 30) x L ~ (0 ~ 35) |